Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

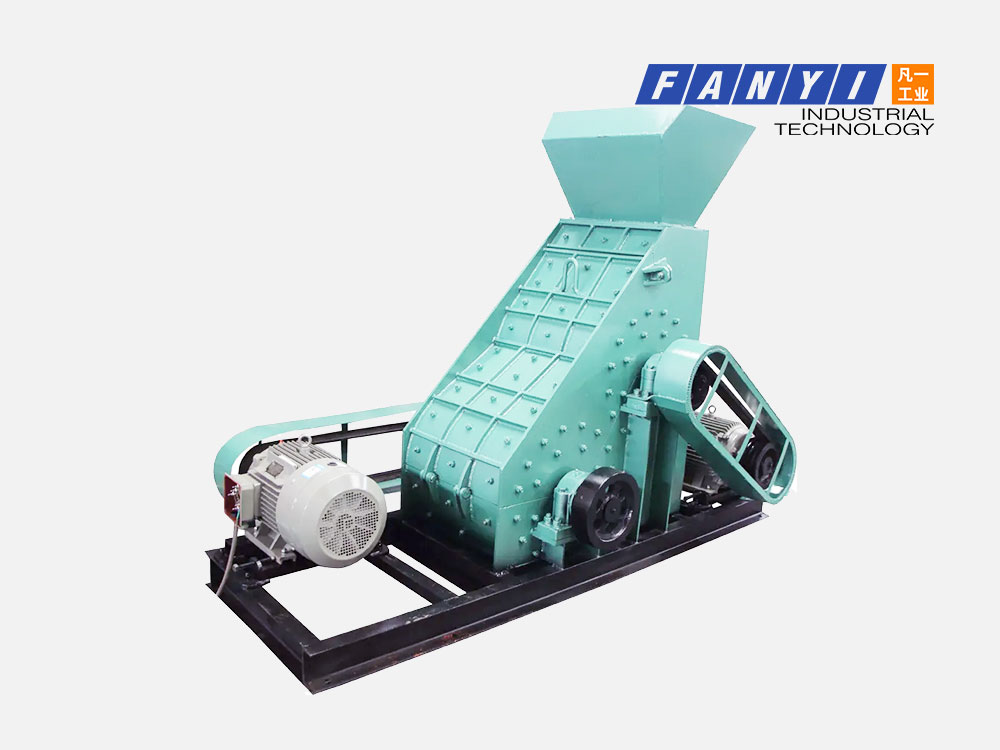

Two-stage is also called double rotor hammer crusher. Some raw materials with a large quantity of water will adhere to the grate bottom so that they can’t be discharged. Thus, we company manufactured the two-stage crusher to solve this problem.

DESCRIPTION

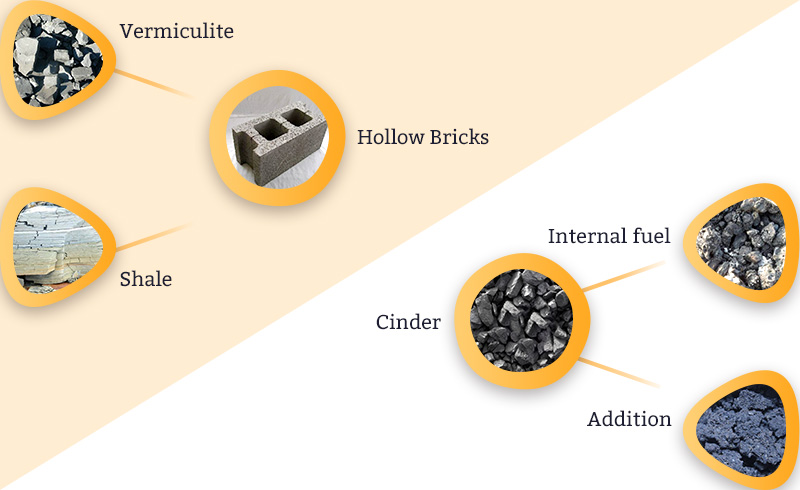

The two-stage crusher has a wide range of applications for crushing gangue, shale, coal cinder, stones, coal slime and other materials with too much moisture. Two-stage crusher is used in the industries such as construction, chemical engineering, metallurgy, mine, ceramics and refractory matter and has many advantages such as good crushing effect, high yield and uniform discharging materials. Two-stage crusher has solved the abrasion problems happening to the old pulverizer’s hammerhead and scale board.

The two-stage crusher is composed of box, rotor, hammer, counter lining, sieve plate. Based on the traditional small hammer crusher, the double stage crusher or the two-stage crusher has been improved a lot, so it is also called double rotor hammer crusher.

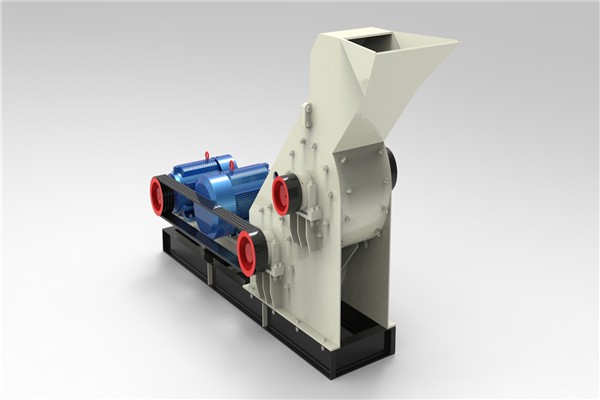

It has two sets of rotors, and can totally crush rock materials twice. The effect of single two-stage crusher is equal to two common crushers.

The two-stage crusher is able to break materials including limestone, bricks and tiles, coal cinder, furnace cinder, slag, gangue and construction waste, etc.

In order to avoid blocking, double-stage crusher does not install the grid and screen, which solved the problem of high temperature and high humidity in the process of crushing. The twin-stage crusher equals two hammer crushers working together.

The reasonable combination realizes the series application of two sets of rotors. Vermiculite and cinder can be used as brick plant additives and internal fuel, while shale and vermiculite can produce standard and hollow bricks.

When it works, the twin-stage crusher’s two rotors revolve at the same time at high speed driven by the double electric motors.

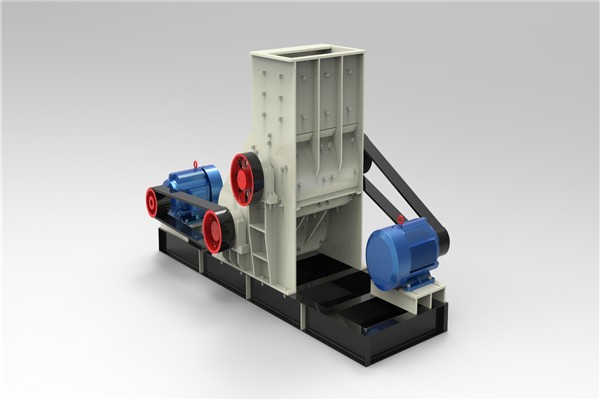

Materials in the crushing cavity are immediately crushed by the lower rotor’s hammerhead with high-speed rotation after first being crushed by the high-level rotor.

Materials are completely impacted with each other and crushed into the coal cinder powder with the discharging size less than 3mm.

| Model | Feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Allowed moisture content of materials | Motor power (kw) | Overall dimension(mm) |

| 2PC1100×1000 | ≤180 | ≤3mm(less than 2mm, more than 80%) | 60-90 | <20% | 90+110 | 4086×2030×2337 |

| 2PC900×800 | ≤120 | 50-70 | 55+75 | 3950×1750×2280 | ||

| 2PC800×600 | ≤120 | 40-60 | 45+55 | 3485×1400×2254 | ||

| 2PC800×600 | ≤120 | 40-60 | 45+55 | 3625×1314×2065 | ||

| 2PC600×400 | ≤100 | 15-25 | 18.5+22 | 2350×926×1630 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.