Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

In metalworking manufacturing, efficiency drives profitability. Yet, manufacturers grapple with persistent challenges: managing metal scrap, coolant waste, and strict environmental regulations. Scrap accumulation disrupts workflows, haul-away expenses drain budgets, and outdated methods sap productivity. What if these obstacles could be transformed into opportunities to boost efficiency, slash costs, and advance sustainability?

We deliver solutions that make this possible. Our cutting-edge equipment—from metal scrap conveyors to industrial wastewater treatment systems—empowers manufacturers to optimize operations, minimize waste, and unlock enduring profitability. We turn metal scrap into a revenue stream.

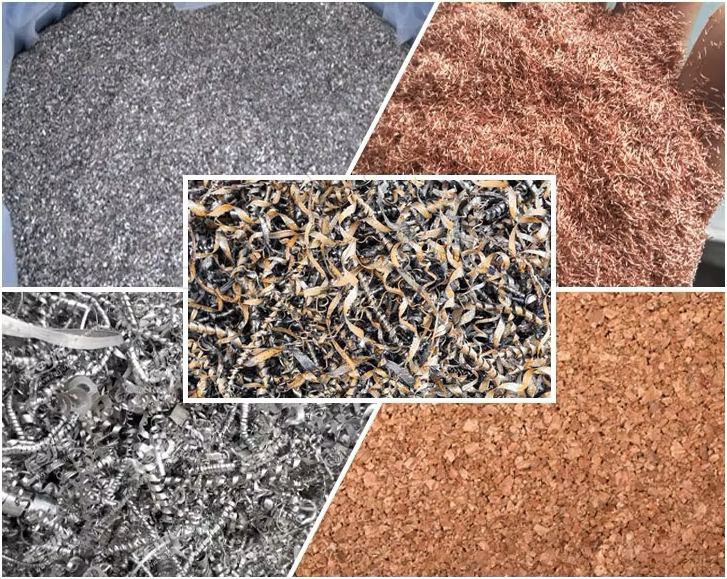

Aluminum chip waste, a common byproduct in metalworking, originates from sources like:

A typical aluminum briquetting operation follows these steps:

Key Insight: Purity matters. For foundries, high-purity aluminum briquettes command premium prices and sell quickly. For in-house use, they yield purer remelted aluminum, boosting profits.

Briquetting transforms aluminum waste into a strategic asset:

Our aluminum briquette machines make this process seamless, converting chips into compact, high-value briquettes that drive efficiency and revenue.