Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

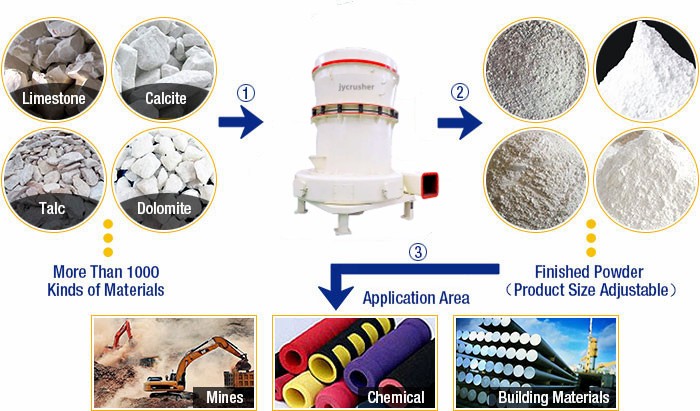

Raymond mill is a high-efficiency closed-circuit fine powder grinding mill plant for non-metallic minerals. The finished particle size is relatively fine and uniform, and could well meet the material requirements of various fields. It is suitable for processing various non-flammable and explosive minerals with Mohs hardness below 7 and humidity below 6%, such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, Kaolin, bentonite, medical stone, bauxite, red iron oxide, iron ore, etc., The fineness of the finished product can be adjusted between 613 micron and 44 micron (0.613 mm -0.044 mm) to meet different requirements through adjusting the analyzer and the fan.