Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

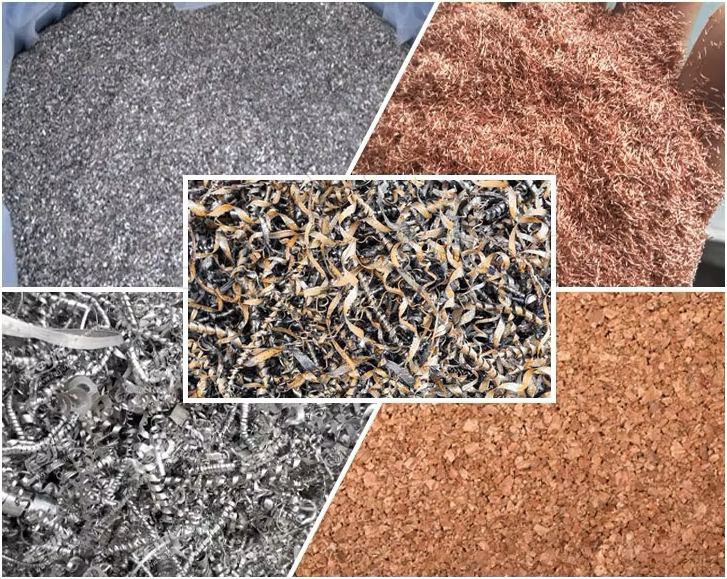

The Scrap metal baling machine uses the hydraulic system to drive the hydraulic cylinder, which outputs high pressure to push the metal chips into the mold and cold press them into cylindrical cake. The Box type small metal chip briquetting machine can compress copper, aluminum, iron, steel scraps and other wastes produced by hardware processing into a single round cake with a diameter of 70mm. It can save the storage space and transportation cost. Cutting oil can be automatically recovered while pressing the cake. The recycling rate reaches more than 95%.

DESCRIPTION

In an aluminum product processing factory, the lathe produces a large amount of waste aluminum chips during daily cutting and grinding operations. To ensure smooth cutting and grinding, cutting oil is often added, which leaves residue on the aluminum chips. This leads to a significant accumulation of scattered aluminum chips.

The Box type metal chip briquetter can compress these waste aluminum chips generated in the workshop. Shavings and flaky chips are first processed through a crusher before being fed into the briquetter. During the briquetting process, the cutting oil present in the chips is collected by a liquid pump for later treatment and reuse.

The compressed aluminum chips are formed into convenient briquettes, making it easier for the workshop to pack, store, and transport them. Additionally, recycling these briquettes by remelting them significantly improves furnace efficiency.