Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

The ultrafine ring roller mill can grind non-metallic ores with a Mohs hardness of less than 7, and the fineness can be flexibly adjusted. The equipment occupies a small area, is easy to operate, highly efficient and energy-saving, and environmentally friendly and pollution-free. The customer’s ring roller mill production line is mainly used for fine grinding of carbon black after tire pyrolysis.

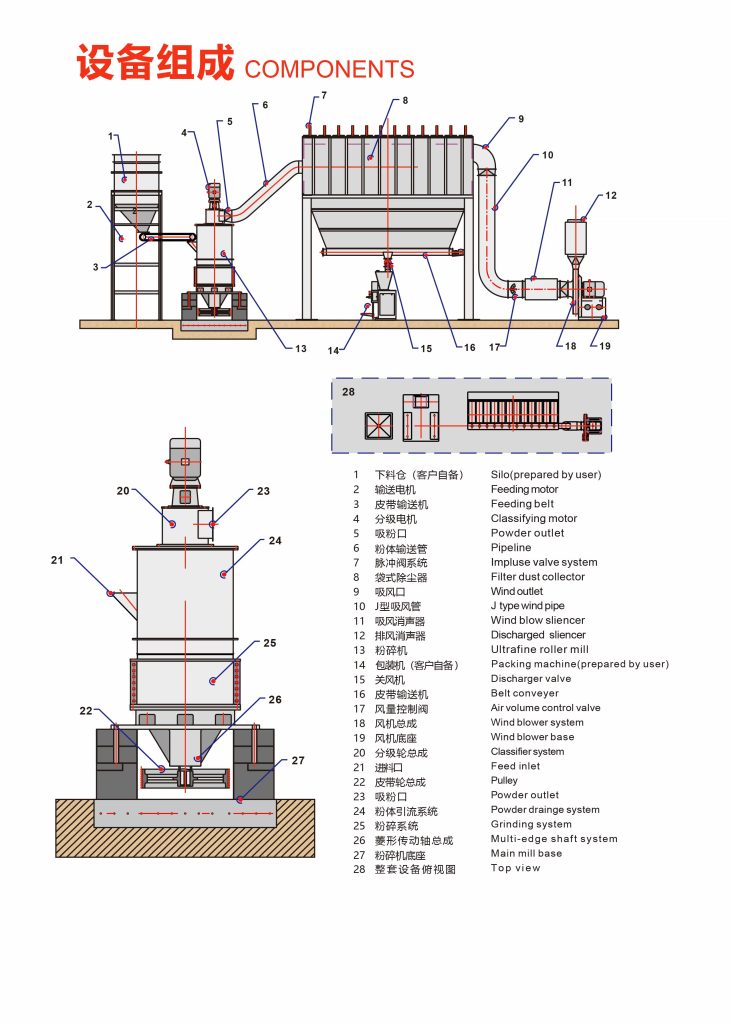

DESCRIPTION

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill. It is a grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

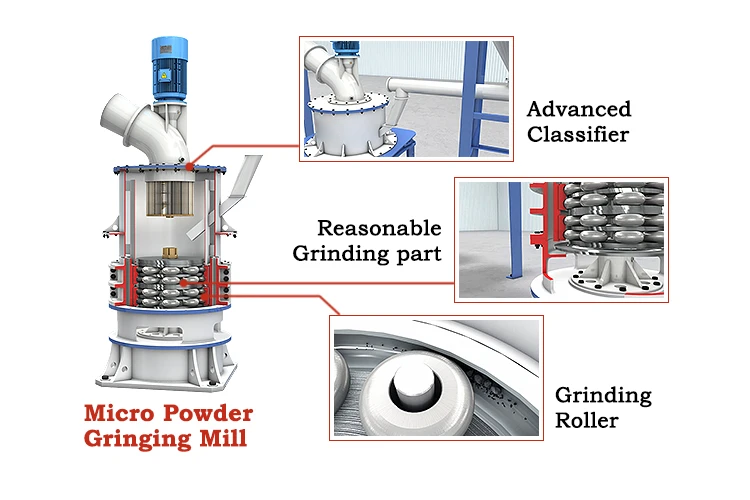

As the name suggests, the micro powder roller mill mainly crushes the material by rolling and grinding the multi-layer ring rollers. It is mainly used to produce ultrafine powder of 8-45μm.

Our common micro powder roller mill models have 21 rollers, 28 rollers and 34 rollers. The greater the number of grinding rollers, the greater its output.

The ring mill operates on the principle of compression and grinding.

It consists of 3 or 4 grinding rings and several grinding rollers. The material is fed into the center of the rotating grinding ring.

As the ring turns, centrifugal force pulls the material to the edge of the ring. At the edge, the material is ground between the ring and the rollers.

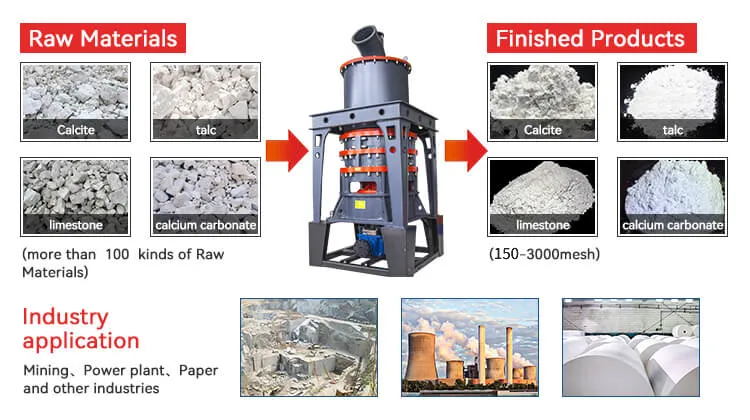

Widely used in the production of ultrafine calcium carbonate for applications in the plastics, paper, and paint industries.

Suitable for grinding various minerals and ores. Mainly used for grinding non-metallic ores with Mohs hardness below 6 and some metal ores. For example limestone, calcite, dolomite, gypsum, barite, marble, kaolin, talc, iron ore, mica, bentonite, chalk, illite, pyrophyllite, pumice, sepiolite, magnesite, diatomite, graphite, fluorite, rock phosphate, fly ash, etc.

It can also be used for grinding glass, bamboo powder, egg shells, etc.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Note: