Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

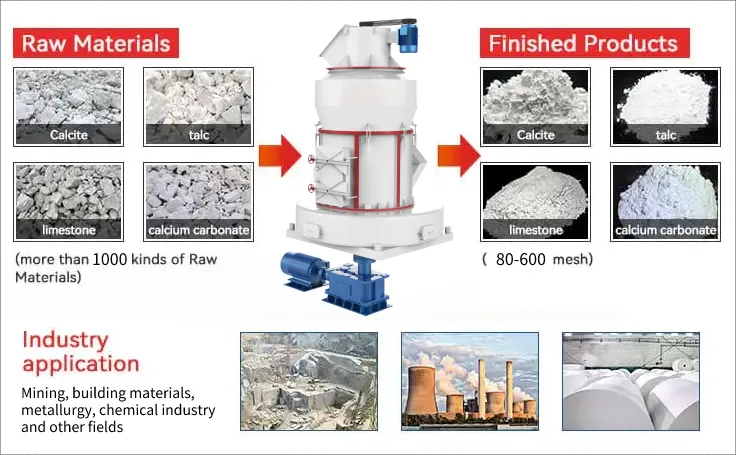

Applied materials: various non-flammable and explosive minerals such as gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, iron ore, etc.

DESCRIPTION

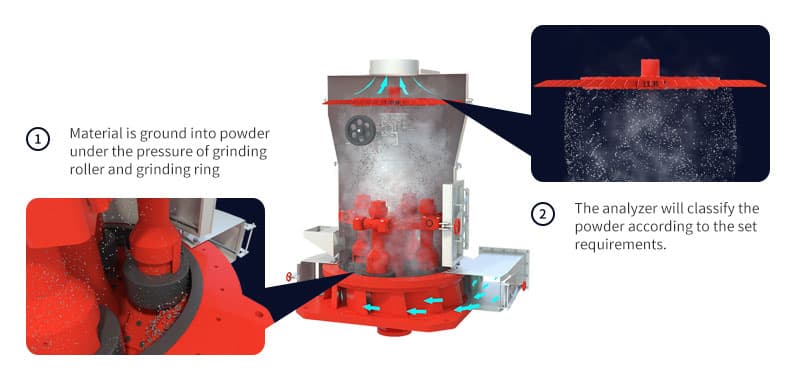

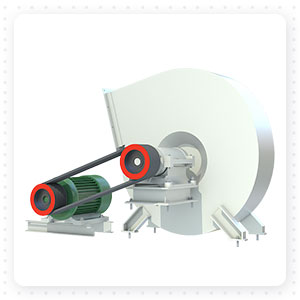

The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications. It is an efficient fine grinding machine for large-scale powder production.

Raymond mill is widely used in chemical fertilizer, chemical product, and mineral industries to grind non-combustible and non-explosive non-metallic materials with Mohs hardness below 9.3 and humidity below 6%. It is an excellent grinding machine for barite, calcite, calcium carbonate, potassium, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, etc.

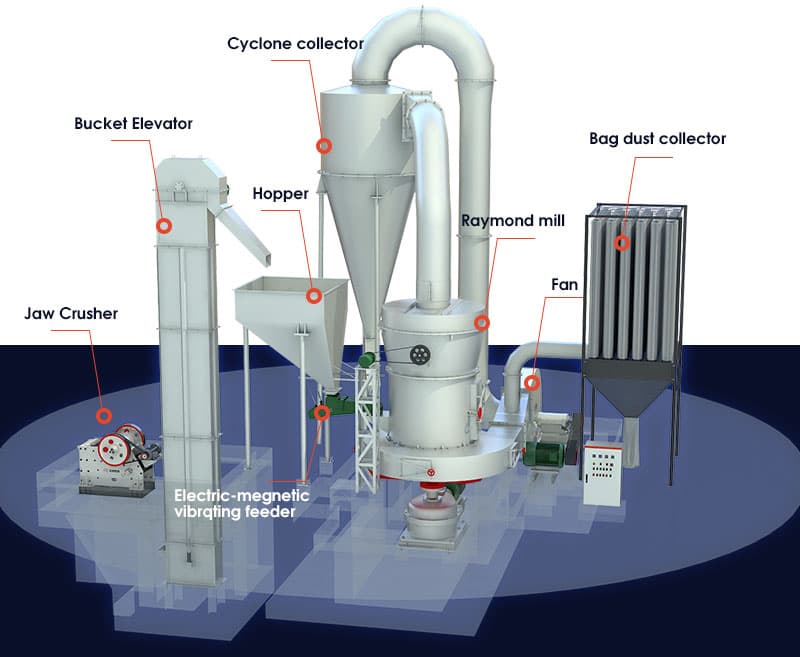

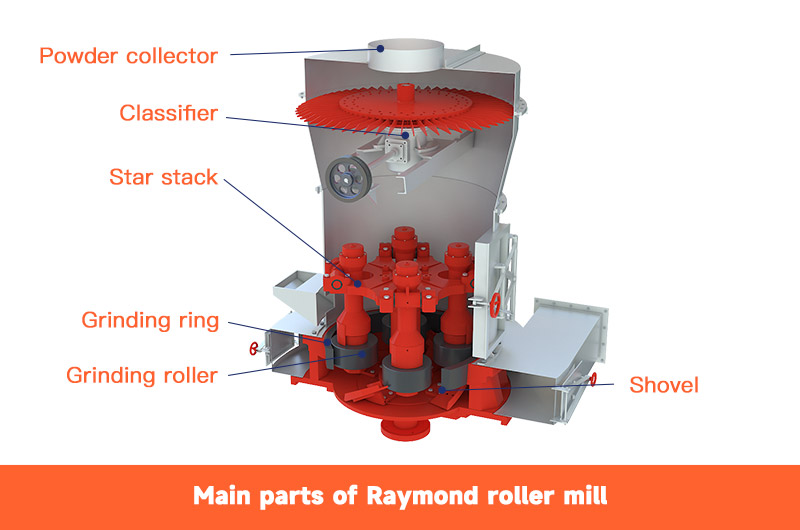

Raymond mill is mainly composed of Roller, Ring, Shovel, Shovel base, Bearing, Roller bushing, Spring for roller, Roller hanger, Reducer, Main shaft, Bevel gear & pinion, Classifier, Blower, Locking nut, Roller assembly, Snail shell, Motor, Elevator, Chain, Vibrating feeder, Crusher, etc.

Outputs of 8 to 176 tons per shift (8 hours). The finished powder is uniform in fineness, and the passing rate is as high as 99%.

Different uses of powder require different particle sizes. Therefore, the fineness of the Raymond mill can be adjusted arbitrarily between 0.173mm and 0.044mm. The achievable upper particle size is 800 mesh.

The Raymond pendulum mill achieves high requirements for grain size distribution easily and extremely energy efficiently, even in case of the highest demands regarding the fineness to be achieved.

Less vibration due to integral gearbox increasing the mass of the mill and special designed anti-vibration device. Vibration reduction avoids cracking or damage to the frame and return box from long-term vibration and fatigue. The important parts are made of high-quality steel, and the wearing parts are made of excellent wear-resistant materials to improve wear resistance.

The good sealing performance of the equipment and the full-pulse dust collector ensure that the dust removal rate can reach 99%.

The electrical system adopts centralized control, and the grinding workshop can basically achieve unmanned efforts.

| Parameter Model | 3R1410 | 3R2115 | 3R2615 | 3R2715 | 3R3015 | 4R3016 | 4R3216 | 5R4119 |

| Feeding size (mm) | <8 | <15 | <15 | <15 | <20 | <25 | <25 | ≤30 |

| Size of finished product (mm) | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.044 |

| Shift output of different material fineness (t) | 0.6-9 | 1-20 | 1.5-25 | 2.8-33 | 3-36 | 3.5-40 | 4-52 | 8-78 |

| Rotate speed of central shart (r/min) | 274 | 190 | 170 | 161 | 148 | 140 | 130 | 105 |

| Grind roller Q’ty | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 5 |

| Grinding ring Outer Dia (mm) | 525 | 725 | 850 | 907.5 | 973 | 1006 | 1050 | 1400 |

| Grinding roller Outer Dia (mm) | 150 | 210 | 250 | 270 | 300 | 300 | 310 | 410 |

| Height of pulverizing roller (mm) | 100 | 150 | 150 | 150 | 160 | 160 | 170 | 190 |

| Main Motor (kW) | 7.5 | 15 | 18.5 | 22 | 30 | 30 | 37 | 75 |

| Fan Motor | 4-5.5 | 4-11 | 4-15 | 4-18.5 | 4-22 | 4-22 | 4-37 | 4-75 |

| Analyzer Motor | 6-1.1 | 6-2.2 | 6-2.2 | 6-2.2 | 6-2.2 | 6-3 | 4A-5.5 | 4B-7.5 |

| Overall dimension (mm) | 3340*2200*3200 | 4480*3100*3970 | 5000*4100*4850 | 5050*4150*4900 | 5200*4200*4950 | 5250*5000*5500 | 7700*7200*8800 | 7900*8800*9650 |

* The specifications are approximate and will vary depending on the options selected.

* Can be customized according to customer needs.