Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

The Aluminum Dross Recovery Machine is a crucial tool in the aluminum recycling industry, dedicated to reclaiming valuable aluminum from a byproduct known as dross.

The processing capacity can be 100 to 650kgs based on different aluminum dross recovery machine models.

DESCRIPTION

Our company provides complete aluminum slag recycling and processing solutions, including grinding, crushing, screening, processing, separation, cooling and bagging. We will do more than you expect.

Aluminum dross recovery machine is featured with separating the aluminum and dross by one time, high efficiency for recycling rate(90% of aluminum from the dross),short working time, low energy consumption, environmentally friendly and no need any fuel in the process.

The whole machine is fully automatic in a mechanical working way and its efficiency is increased 15% compared with the manual way.

Aluminum Hot Dross Recycling Machine is mainly used for separating or extracting the aluminum metal form the Aluminum dross or aluminum slag (aluminum waste) or aluminum ash, it can reuse the aluminum metal from the aluminum dross to avoid wasting. It is special designed to recovery the hot aluminum dross, aluminum ash, aluminum slag that generated from the aluminum melting furnaces or holding furnace.

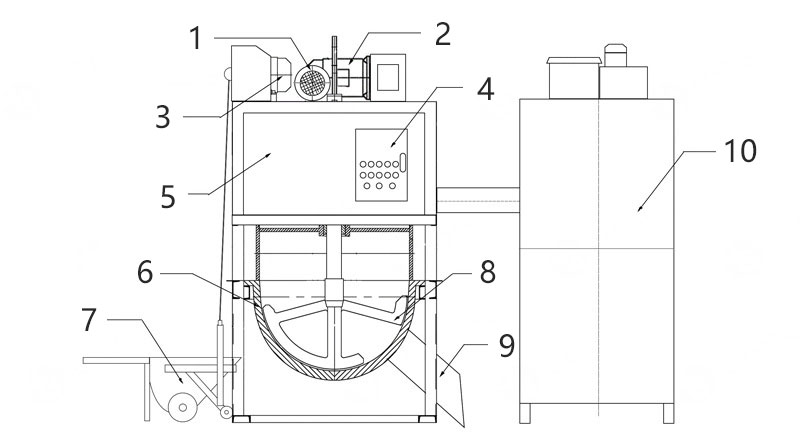

Aluminum dross processing machine, heatproof pot, dross trolley, cyclone dust collector and electric control box.

| Model | 700 | 900 | 1100 | 1300 |

| Voltage (v) | 380 | 380 | 380 | 380 |

| Main motor (KW) | 4 | 4 | 5.5 | 7.5 |

| Transmission motor (KW) | 1.5 | 1.5 | 1.5 | 1.5 |

| Lifting motor (KW) | 0.75 | 0.75 | 1.5 | 1.5 |

| External dimensions (mm) | 1200*1200*2850 | 1400*1300*2900 | 2100*1800*3300 | 2300*2300*3500 |

| Stir frying pan size (mm) | φ700*670*50 | φ900*700*60 | φ1100*760*65 | φ1300*900*65 |

| Volume (L) | 200 | 350 | 650 | 1000 |

| Spindle diameter (mm) | φ60 | φ90 | φ100 | φ120 |

| Discharge port size (mm) | 300*250 | 300*250 | 300*250 | 300*250 |

| Exhaust port (mm) | 300 | 370 | 370 | 370 |

| Processing temperature (℃) | ≥700 | ≥700 | ≥700 | ≥700 |

| Capacity (kg) | 100-150 | 150-200 | 200-400 | 400-600 |

Note: 1. The output may vary depending on the material.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.

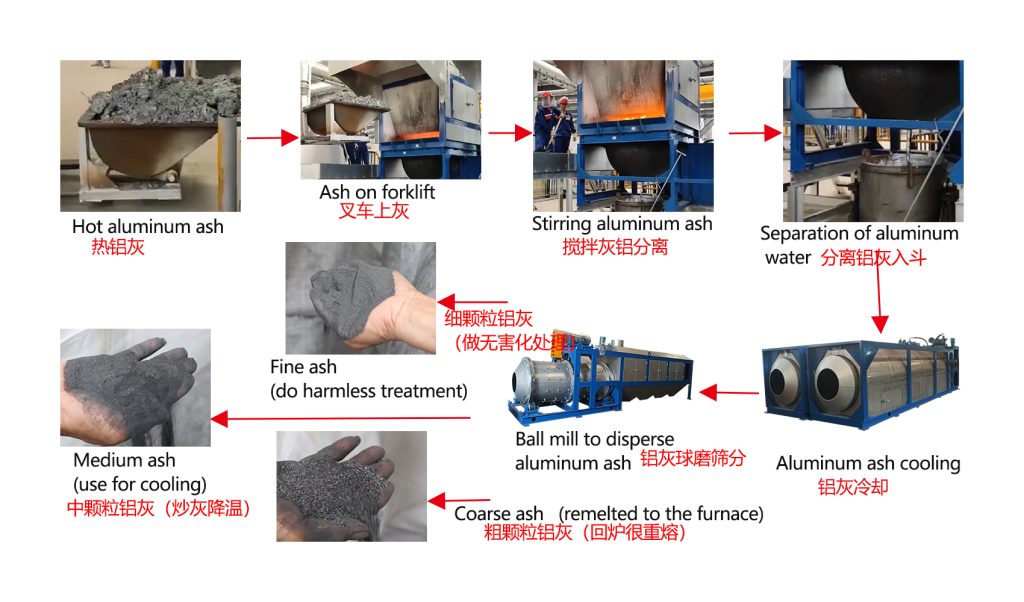

First, pick up the hot aluminum ash from the melting furnace and put it into the aluminum ash hopper. Use a forklift to load the ash. The hot aluminum ash enters the fry ash pan. The stirring paddle is used to stir. After stirring, the molten aluminum and the aluminum ash are separated, and the molten aluminum flows into the aluminum hopper. , After the aluminum water flows, the remaining aluminum ash enters the ash cooler, which uses water spray to cool to below 80 degrees, and the cooled aluminum ash enters the ball mill sieving machine for ball milling and crushing of the aluminum ash. The crushed aluminum ash enters a three-stage sieve to separate out fine-particle aluminum ash, medium-particle aluminum ash and coarse-particle aluminum ash. Among them, the fine-particle aluminum ash is awakened and harmlessly treated, the medium-particle aluminum ash is used to cool the ash during frying, the coarse-particle aluminum ash is directly returned to the furnace for remelting, and the aluminum ash recovery production line, the aluminum recovery of aluminum reaches more than 90%.

Aluminium dross recovery machine is on-site processing, As Aluminum melting point is 660℃ light alloy.

When the temperature of aluminum gets more than 660℃, all aluminum will become liquid aluminum and can be separated from the dross and slag.

Aluminium dross recovery machine is designed on the basis of the difference of physical property and the specific gravity between the solid materials and liquid materials.