Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

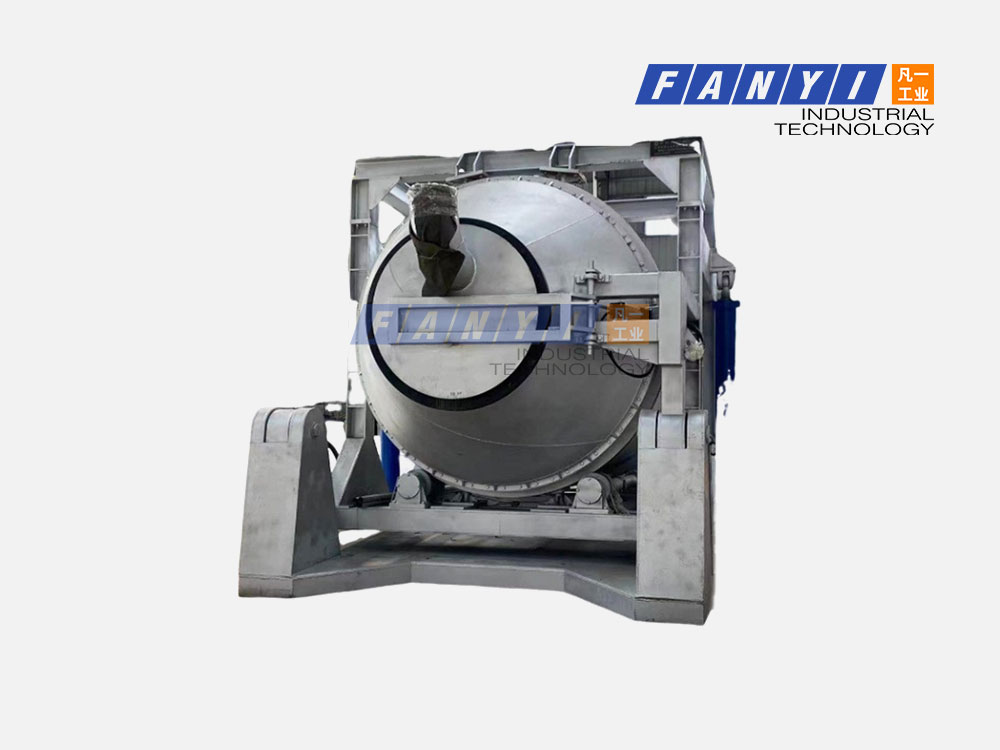

Aluminum dross rotary furnace is one kind of necessary equipment in the aluminum dross processing of recycled aluminum industry, which is one important part that reflects operation cost and profile of recycled aluminum recycling.

Aluminum dross rotary furnace is a tilting fully automatic aluminum dross rotary furnace, which is specially used for dross processing and recycling.

DESCRIPTION

Aluminum dross tilting rotary furnace is suitable for mass treatment of hot slag, cold slag and aluminum dross containing high iron. The number of people is small. Only one skilled forklift worker and one auxiliary worker can handle several tons to dozens of tons of hot aluminum slag a day, and the work efficiency is very high. The hot slag raked out from the furnace is sent to the rotary furnace with a rotary forklift. The aluminum molten in the aluminum slag can be separated by using the backward rotation of the rotary furnace and the front and rear mixing of the forklift rake. Pay attention to controlling the temperature during operation. Cold slag or small raw aluminum can be added as a temperature control agent and secondary refining. Rotary furnace and screening cold ash bucket are ideal equipment to replace crucible and vertical ash recycling machine to deal with aluminum slag and cold slag in large quantities.

The aluminum dross rotary furnace does not need heating device for the treatment of hot slag and cold slag. In particular, when dealing with cold slag, it can be operated continuously only with a bucket of hot slag raked out from the furnace. In addition to the electric energy of equipment operation, there is no additional energy consumption in the operation process. Due to the centralized treatment, the generated dust is convenient for centralized collection, which truly achieves energy conservation and environmental protection.

This equipment recycles and reuses the ash raked out of the smelting furnace. The rotary furnace is used in a plant that processes slag in large quantities. After treatment, it can also be put into your ash cooler for cooling and sorting. The sorted ash is fine, medium and coarse. The fine ash can be directly sold out. The medium ash and coarse ash can be added into the rotary furnace and returned to the furnace as coolant, which can make the recovery of aluminum slag aluminized, and the economic benefit is very obvious.

The process of aluminum dross in the rotary furnace is inside heating, it means that we use the heat coming from aluminum dross self-ignition (during the high-temperature period of self-ignition, waiting for the heating between the stirring of high-temperature aluminum dross ), so that can improve the melting speed of aluminum and aluminum liquid temperature, reduce aluminum viscosity, easy for the separating aluminum liquid and aluminum ash.

Aluminum dross rotary furnace can extract aluminum metal in the aluminum dross from 40-60% to 15-17%, with a high aluminum metal recovery rate (about 80%).

The dust generated in the production process gets controlled, not only reduce the working strength, but also improve the dross processing environmental pollution.

Common heating methods include electric heating, gas heating, fuel heating, etc.

Select the appropriate heating method based on energy supply, cost and requirements.

| Specifications And Models |

The Furnace Body Size (mm) |

Kind Of Drive | Processing Power (t) |

| 2T | Φ1800×3500 | Main motor: sprocket chain drive // barrel body: friction drive between ring track and supporting wheel | 2 |

| 3T | Φ2000×3600 | 3 | |

| 5T | Φ2300×4580 | 5 | |

| 8T | Φ2500×5180 | 8 | |

| 10T | Φ2800×5680 | 10 | |

| 12T | Φ3000×6150 | 12 |

Note: 1. The output may vary depending on the material.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.

Aluminium Dross, Recycling System