Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

An Aluminum Dross Cooling Machine plays a crucial role in the aluminum recycling industry. It tackles the challenge of safely and efficiently cooling down hot dross generated during various melting processes.

DESCRIPTION

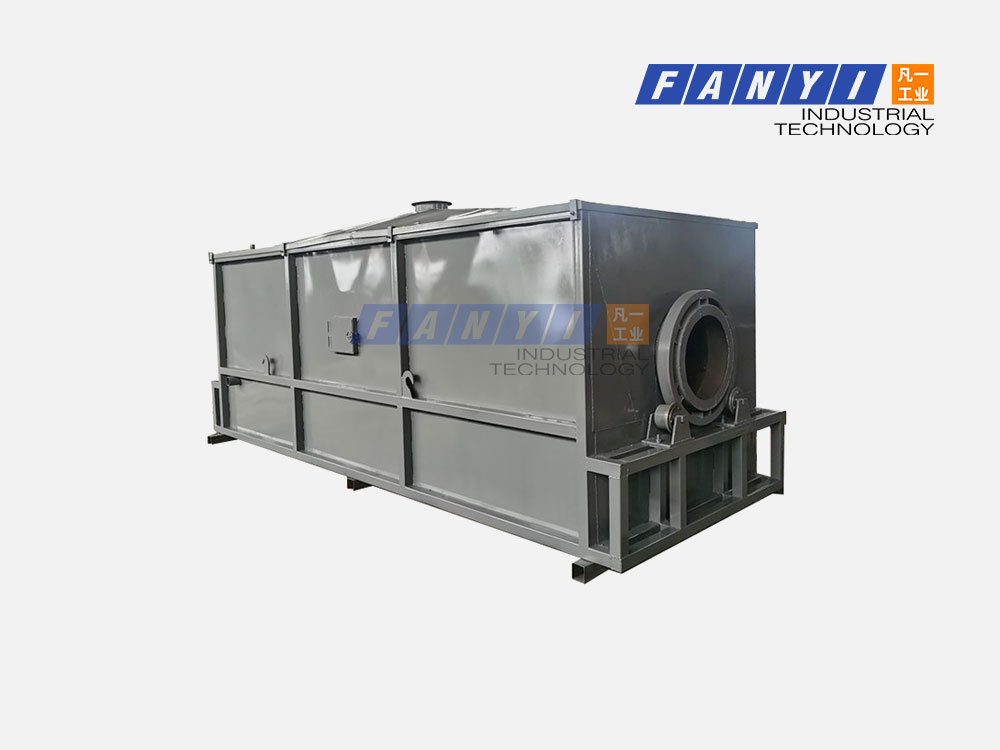

Aluminum Dross cooling machine, Aluminium Dross Cooling System

The hot aluminum ash cooler adopts circulating water spraying method to quickly cool the hot aluminum ash. The temperature of the hot aluminum ash in the wok can be as high as 700℃. When passing through the cooler, under the action of circulating water, the hot aluminum ash The ash is rapidly cooled to below 80°C, which can reduce the burning loss of aluminum metal and minimize the loss of metal aluminum.

Cooling method: spray cooling

Speed of cold ash bucket: 3-20r/min

The temperature of aluminum ash after cooling: ≤80℃

Cold ash bucket processing capacity: >1·5-2·5t/h