Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

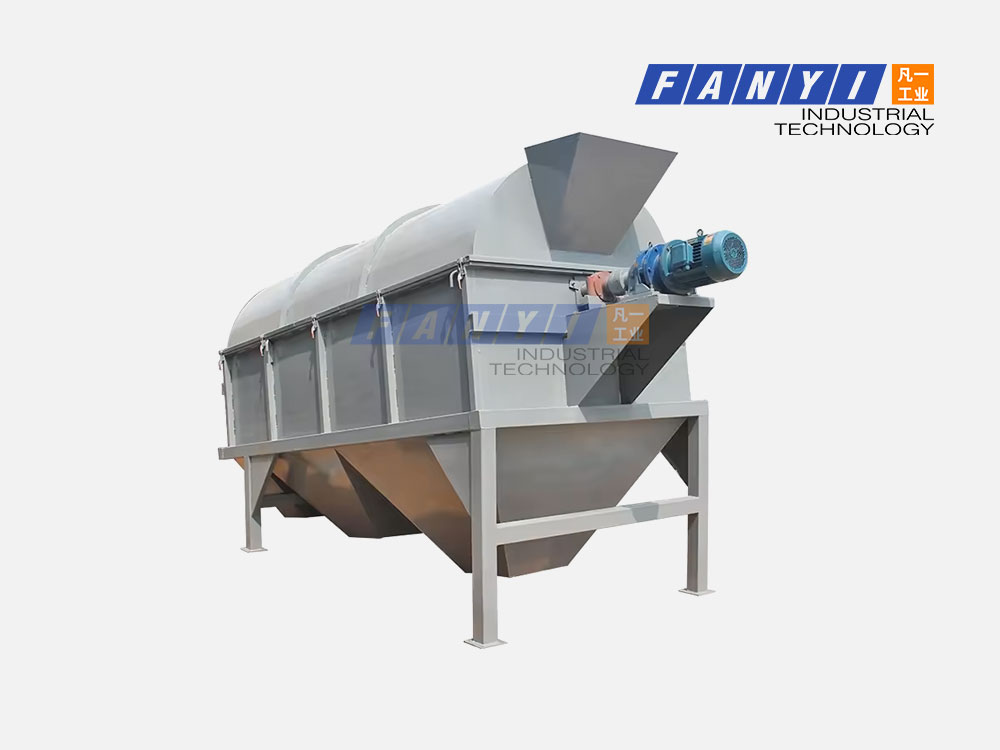

Trommel screen consists of five parts as drum, frame, hopper, reducer and motor. After the broken stone into the drum, on the one hand, materials being screened along with the rotation of drum, on the other hand, the bigger materials flow forward along the direction of slope and be separated by the screen with different number of meshes. The different materials fall into different hopper and then be sent to different finished product stacks by manpower or belt conveyor.

DESCRIPTION

Mineral Trommel Screen For Sieving Coal Ash Slag Mixture Rotating Drum Sieve

The main structure of Mineral Trommel Screen For Sieving Coal Ash Slag Mixture Rotating Drum Sieve is cylindrical drum, which is inclined and installed on the frame. The geared motor is connected to the drum device through a coupling, and the driving drum will rotate around the axis direction. When the materials enters the tilting and rotating drum device, the materials on the screen surface is overturned and rolled so that the fine materials are discharged from the discharge port at the bottom of the drum of trommel screen, while the coarse materials are discharged from the discharge port at the tail of the drum. As the materials in the drum turn and roll constantly, the materials stuck in the screen can be ejected to prevent the sieve blocking.

Our Mineral Trommel Screen For Sieving Coal Ash Slag Mixture Rotating Drum Sieve can be used in chemical, coking plant, mine, power plant, building materials, metallurgy and other industries, commonly used in medium and fine material classification screening, in order to improve the quality of materials.

| Model | Drum diameter(mm) | Drum length (mm) |

Power (kw) |

Capacity (m³/h) |

Discharge Size (mm) |

| GT620 | 600 | 2000 | 0.75 | 1-5 | 0-100 |

| GT825 | 800 | 2500 | 1.1 | 2-10 | |

| GT1030 | 1000 | 3000 | 2.2 | 10-30 | |

| GT1235 | 1200 | 3500 | 4 | 20-50 | |

| GT1540 | 1500 | 4000 | 5.5 | 30-80 | |

| GT1850 | 1800 | 5000 | 7.5 | 80-150 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.