Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

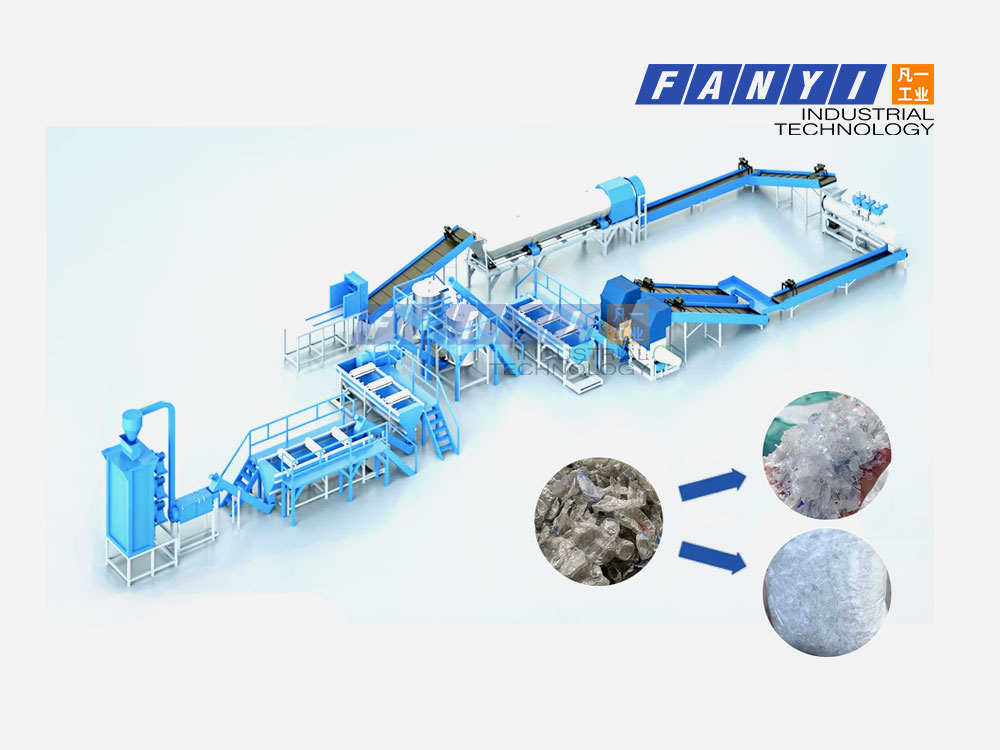

HDPE/PET Plastic Recycling Washing Line Machine is designed for recycling daily-use plastic products. Through grading, crushing, and washing, clean and reusable materials can be obtained for downstream use.

Recycling & Material

DESCRIPTION

PET Bottle Recycling Machine is specialized equipment designed to process used polyethylene terephthalate (PET) bottles and convert them into reusable raw materials. This machine typically performs functions like shredding, washing, drying, and pelletizing, effectively preparing the PET for remanufacturing into new products such as fibers, containers, or automotive parts. The efficient operation of a HDPE/PET recycling machine not only helps in reducing plastic waste but also supports eco-friendly practices by promoting the circular economy.

1. Specially designed for recycling PET bottles of various types, PET bottle crushing, cleaning and recycling line is the equipment for waste PET bottle crushing, cleaning, bottle cap label separating, drying and packaging.

2. The production line consists mainly of bale opener, screw loader, trommel screen, pre-washer, conveyor belt, label remover, sorting platform, crusher, horizontal packing auger, floating tank, dewatering machine, hot washer, high speed friction washing machine, wind conveyor, pipe dryer, paper/PVC/label separation, silo storage and electric panel.

3. Featuring high automation, low energy consumption, high efficiency and clean washing, the entire equipment turns waste PET bottles to recyclable PET bottle pieces effectively.

Belt conveyor → De-Baler(bale breaker) → Belt conveyor → De-label(label remover) → Manual sorting table → Metal detector(or metal seperator) →Belt conveyor → Wet crusher → Screw conveyor(spiral conveyor) → High speed friction washing machine → Screw conveyor → Floating washer → Screw conveyor → Hot washer → Screw conveyor → Floating washer → Screw conveyor → Dewatering machine → Pipe drying system → Zig zag air separator → Storage hopper → Electric control panel

| Model | Capacity (kg/h) |

Power Consumption (kW) |

Water Consumption (ton/h) |

Humidity Content |

| 500 | 500 | 150 | 4-5 | <3% |

| 1000 | 1000 | 220 | 7-8 | <3% |

| 1500 | 1500 | 300 | 10-15 | <3% |

| 2000 | 2000 | 360 | 16-20 | <3% |

The HDPE/PET plastic recycling washing line machine can be customized per your request.

The operation of a HDPE/PET Plastic Recycling Machine generally involves several key steps. Firstly, the machine collects and feeds the HDPE/PET Plastic into a shredder, where they are broken down into smaller pieces. Next, these pieces are washed to remove contaminants such as labels, adhesives, and dirt. Following the wash, the clean PET flakes are dried and often pelletized, turning them into small pellets or granules that can be used by manufacturers to create new products. The entire process helps minimize environmental impact and conserves resources.

Utilizing an HDPE/PET Plastic Recycling Machine provides numerous benefits. First, it significantly reduces plastic waste in landfills and oceans, combating pollution. Second, recycling HDPE/PET Plastic conserves natural resources and energy compared to producing new HDPE/PET Plastic from virgin materials. This machine also fosters economic opportunities by creating jobs in the recycling industry. Converting waste into functional materials supports sustainability efforts and encourages responsible consumption, ultimately benefiting the environment and society.

Most PET Bottle Recycling Machines are capable of processing a wide variety of PET bottles, including those used for beverages, household products, and personal care items. It is crucial, however, to ensure that these bottles are adequately cleaned to remove any residual liquids or contaminants. Labels made from paper or plastic can typically be processed; however, heavily adhesive or multilayered packaging might require additional processing techniques. Familiarizing oneself with the machine’s specifications can optimize the recycling process.

STEP 1 Bale opener

Usage: Open the PET bottles’ bale before crushing and washing

Material: carbon steel equipped with an operation platform

STEP 2 Conveyor Belt

Usage: Carry and transport plastic materials

STEP 3 Trommel Screen

Usage: material sorting according to the particle size

STEP 4 Sorting Platform

Usage: Carrying and transporting plastic materials.

STEP 5 Label Remover

Usage: Remove the labels of the PETbottles

STEP 6 Pre-Washing

item: Pre-washing machine usage: Wash the PET bottle

STEP 7 Crusher

Usage: To crush PET bottles with water into flakes .lt can Positive feed with forced

STEP 8 Screw

Usage: Convey the plastic flakes to the next machine

STEP 9 Floating Tank

Usage: Rinse PET flakes, automatically separate bottom caps and other floating debris, and effectively separate varieties of silt and paper scraps.With three push rollers and a small screw conveyor for the PP PE caps

STEP 10 Hot washing

Usage: Can be heated by electromagnetism,coaldiesel. natural gas etc, the water can be 90’C through liquid medicine washing, the PETflakes will be quite clean.

STEP 11 High Speed Friction Washing

Usage: Used to remove the dirty sand of the flakes through high speed friction, thus PET flakes will be very clean

STEP 12 Dewatering Machine

Usage: dry flakes through centrifugally spinning, automatic feeding, and automatic discharging

STEP 13 PVC Separator

Usage: separate the PVC from the material

material: carbon steel