Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

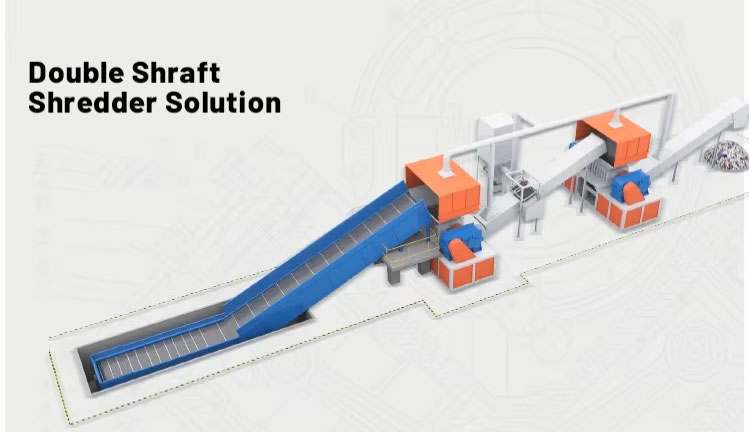

A dual-shaft shearing shredder designed for large-scale waste disposal, it can efficiently and economically shred large items such as various household and office furniture, mattresses, electrical appliance waste (WEEE), etc., reducing space occupation and processing costs, improving transportation efficiency, and promoting recycling and reuse.

The bulky waste shredder uses double motors + double planetary reducers to drive the two cutter shafts to reduce the size of the material through the shearing, squeezing and tearing action of the blades. The distance between the cutter teeth on the blades determines the length of the shredded material, and the thickness of the blade determines the width of the shredded material.

DESCRIPTION

Double-shaft Shredder, also named biaxial shredder, is used to reduce big materials into smaller size, by shearing, tearing and extruding. It is a reliable primary crushing equipment in solid waste recycling. Materials can be various, such as metal (aluminum cans, scraps steel/iron, bicycle/motorcycle/car frame, steel/iron bundles, rubber (waste tire) car engine, and other metal products), biomass, MSW, wood, plastic, cloth, etc. Finished product size is 20-500mm, and capacity can reach 500kg/h-40t/h.

There are mainly eight models: 2S400, 600, 800, 1000, 1200, 1500, 2000, 2600. Each model will be equipped with different configurations (gearbox, motor, blade diameter, blade thickness, blade teeth number…), according to different requirements (type and size of materials, product size after shredded, and capacity per hour).

| Model | 2S-600 | 2S-800 | 2S-1000 | 2S-1200 | 2S-1400 | 2S-1600 | |

| Power | KW | 22×2 | 30×2 | 37×2 | 45×2 | 55×2 | 75×2 |

| HP | 30×2 | 40×2 | 50×2 | 60×2 | 75×2 | 100×2 | |

| Speed of revolution | 8-20rpm | 8-20rpm | 8-15rpm | 8-12rpm | 8-12rpm | 8-12rpm | |

| Reducer | zq500 | zq650 | zq750 | zq750 | zq850 | zsy400 | |

| Different types of reducers can be selected based on the customer’s feeding situation (three shaft reducers, four shaft reducers, hard tooth reducers, planetary reducers, etc.), which affects product prices | |||||||

| Blade thickness(mm) | 20 | 40 | 50 | 60 | 70 | 80 | |

| Blades quantity(pcs) | 30 | 20 | 20 | 20 | 20 | 20 | |

| The thickness and quantity of blades can be customized based on the shredding material and shredding effect | |||||||

| Blades diameter(mm) | 220 | 300 | 400 | 450 | 500 | 600 | |

| The blade diameter, blade tooth shape, and number of teeth of the blade can be customized based on the shredding material and shredding effect, which affects product prices. | |||||||

| Blades material | The material of the blades can be customized according to the customer’s shredding materials (55sicr、5crsi、9crsi、skd11、m6v、h13) and actual usage, which affects the product price | ||||||

| Discharge size | 20-80mm | 30-150mm | 50-200mm | 50-200mm | 80-300mm | 80-300mm | |

| Feeding hopper size (m) |

1*0.8 | 1.2*1 | 1.5*1 | 1.8*1.2 | 2*1.2 | 2.5*1.5 | |

| The size and appearance of the feeding hopper can be customized according to the customer’s feeding situation | |||||||

| Weight(t) | 2.5 | 4.5 | 6.5 | 8 | 10 | 13 | |

| Capacity(t/h) | 0.5-0.8 | 0.6-1 | 1-3 | 1-3 | 2-5 | 2-5 | |

| Overall dimensions(m) | 2.8*1.6*1.8 | 3.5*1.5*2.1 | 4*1.7*2.4 | 4.2*1.8*2.4 | 4.5*2.2*2.4 | 5.2*2.2*2.8 | |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.