Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

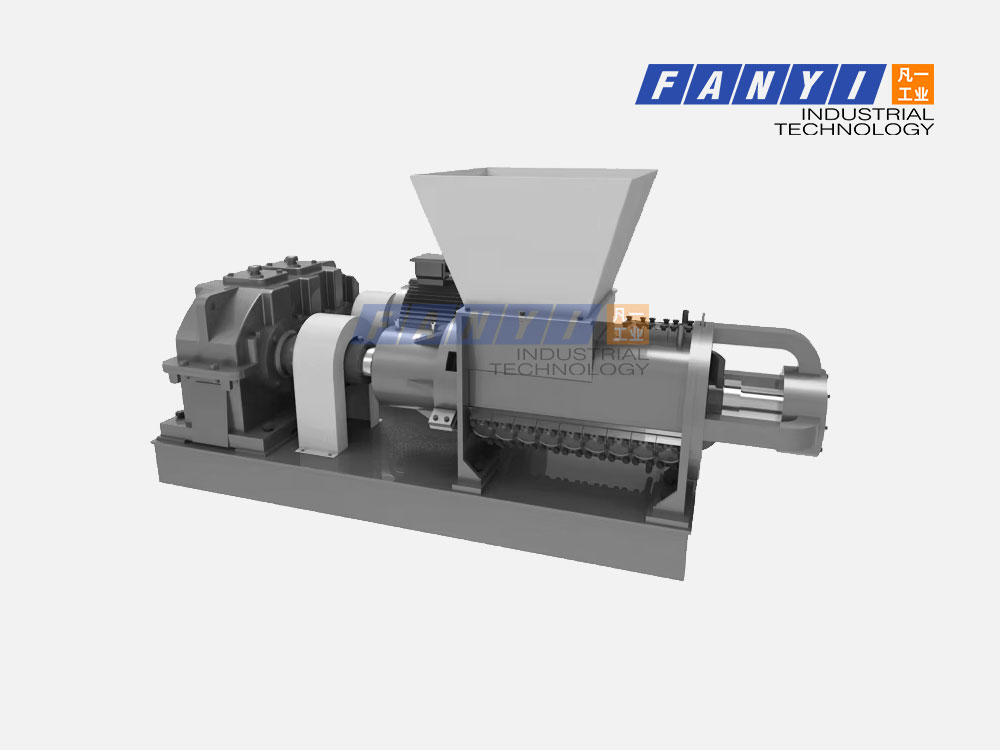

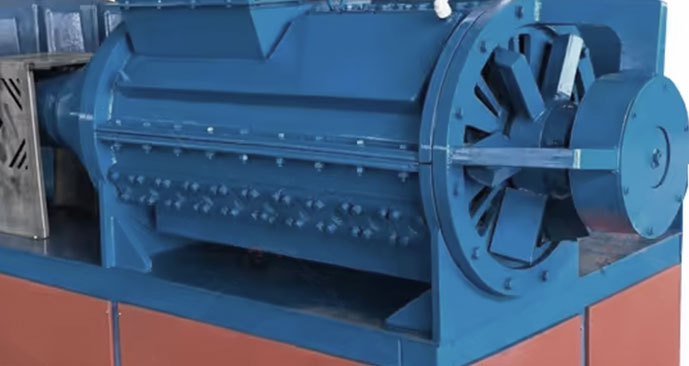

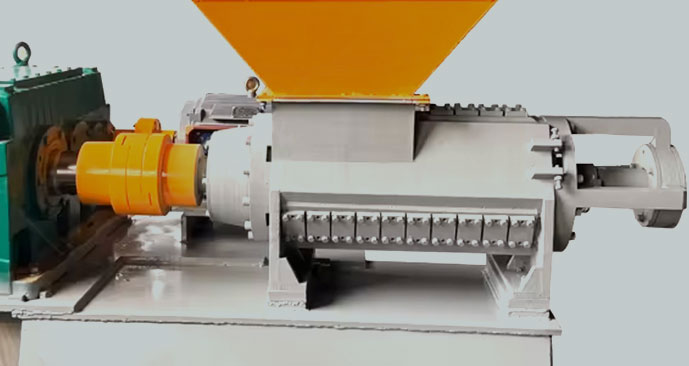

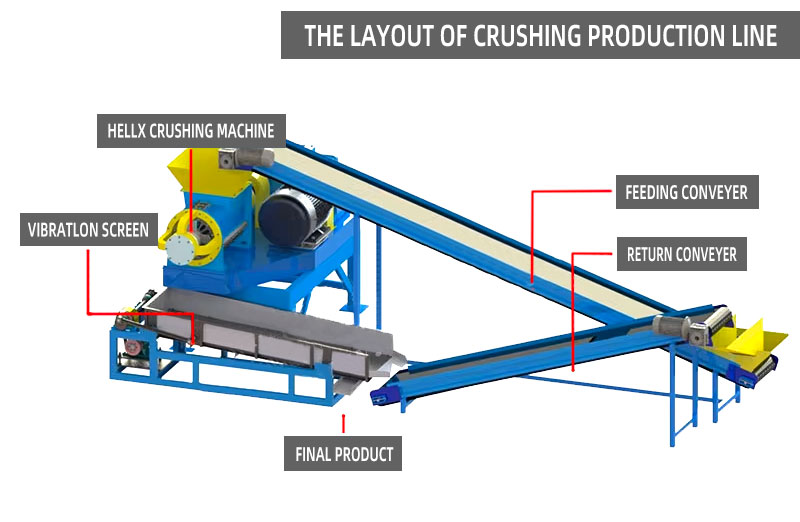

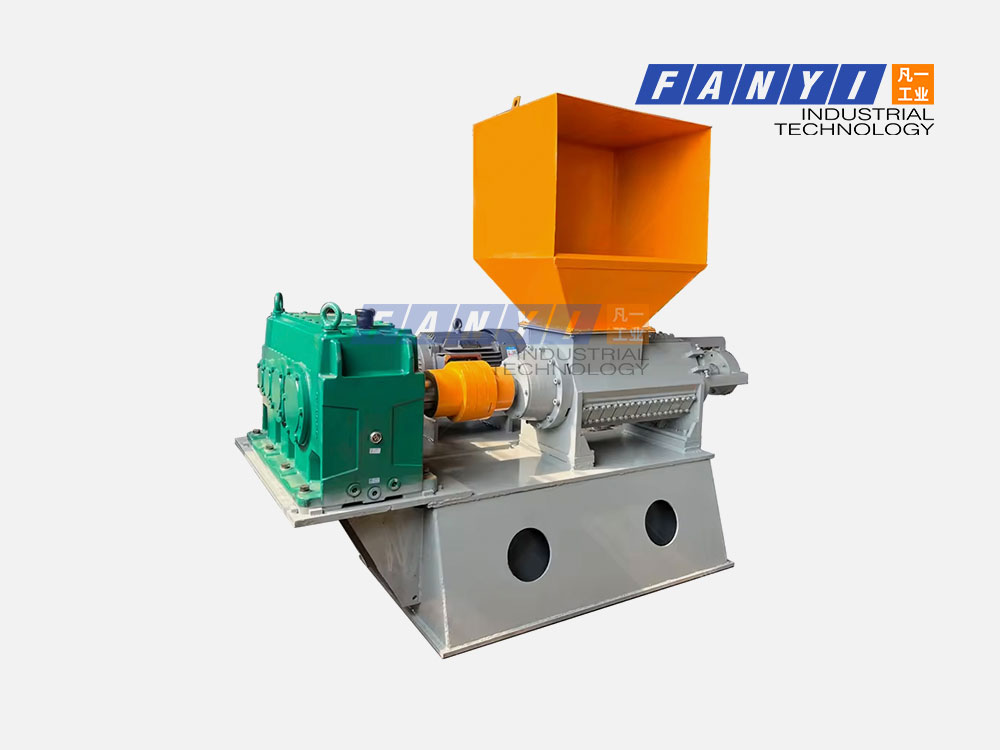

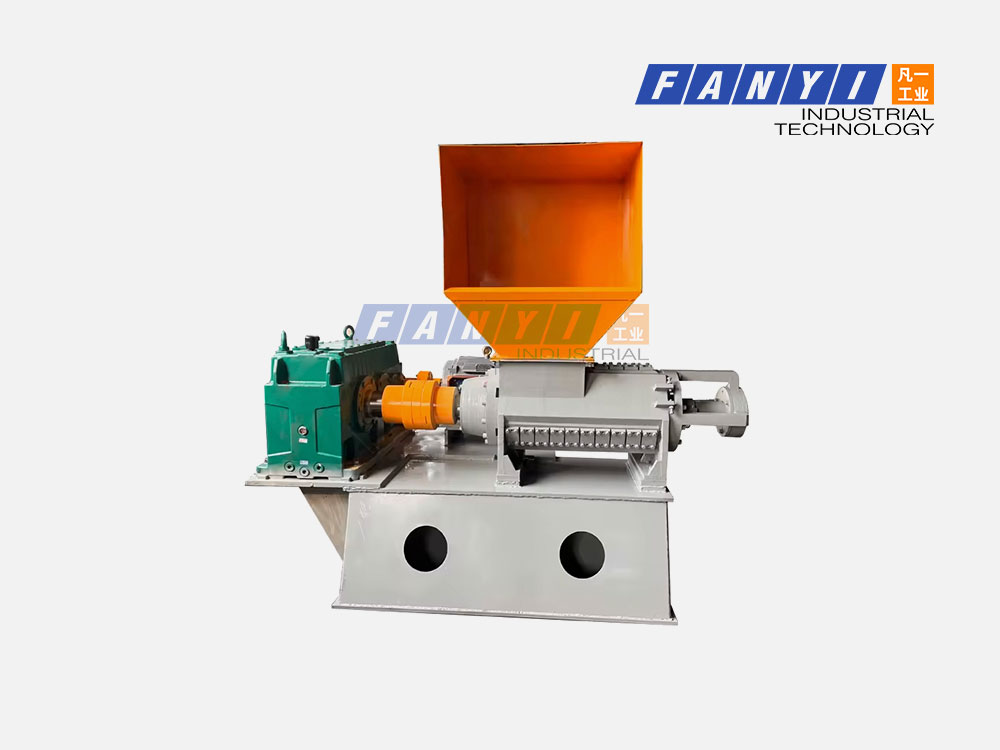

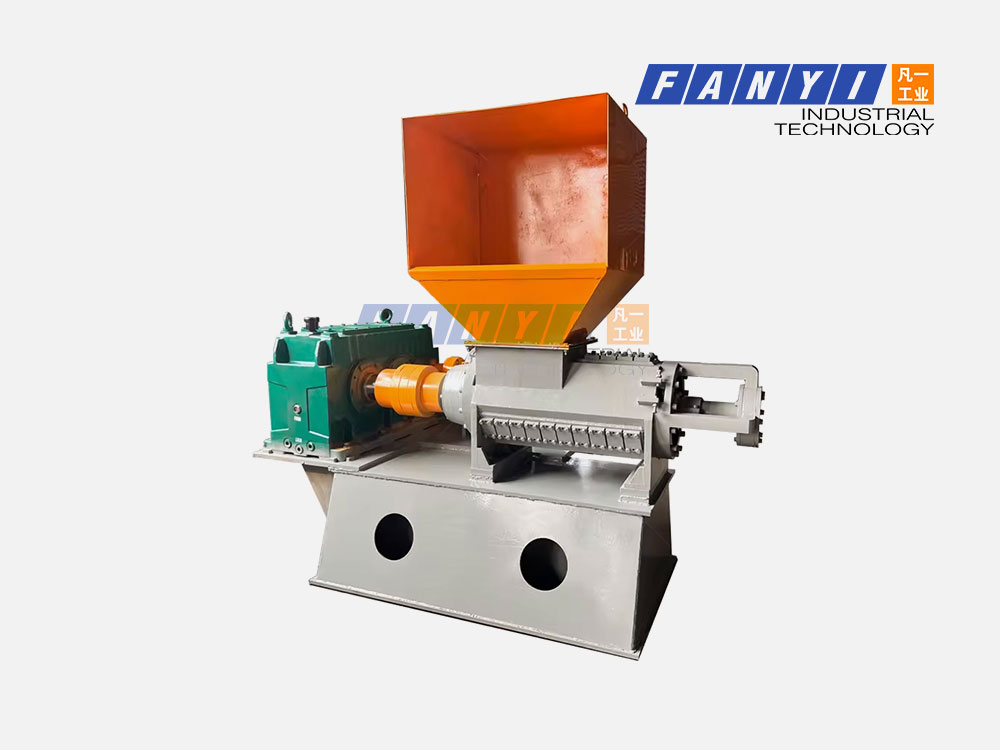

The working principle of the Helix crushing machine is that when the main shaft rotates at low speed, multiple groups of moving knife and fixed knife will repeatedly chop up the material, while producing high strength pressure to the discharge end; In this way, the material is pushed by high pressure, continuously rolling and grinding in the body, and then extruded from the long hole at the end of the body, so as to obtain the ideal size of the material

DESCRIPTION

The new spiral crusher is a multifunctional crusher with wide applications, high output, long life, significant effect, low-speed crushing and adjustable discharge port. It is suitable for materials such as plastic film and rubber. For example, ton bags, plastic bags, nylon cloth, non-woven fabrics, polyester cloth, car interior scraps, EVA sole scraps, old clothes, dustproof cloth, sunshade net, plastic cloth, composite film, winding film, car inner tube, latex products, tires, water rings, soles, washers, rubber factory waste, sealing sheets, conveyor belts, etc.

The machine is composed of a moving knife mounted on the main shaft and a fixed knife mounted on the body. When the spindle rotates at low speed, multiple groups of moving knives and fixed knives will repeatedly chop up the material, while producing high-strength pressure to the discharge end; In this way, the material under high pressure, constantly rolling and grinding in the body, and then extruded from the long hole at the end of the body, and the scraper installed at the end will be chopped again, to get the ideal size of the material, the end of the outlet several long hole, can adjust the size of the outlet, to obtain different sizes of the material particle size.

| Type | XY-300 | XY-350 | XY-450 | XY-550 | XY-650 | XY-850 |

| Reducer | SZY-224 | ZSY-250 | ZSY-315 | ZSY-355 | ZSY-450 | ZSY-560 |

| Power | 45kw-4P | 55kw-4P | 90kw-6P | 110kw-6P | 160kw-6P | 220kw-6P |

| Speed of main shaft (r/min) | 49r/min | 49r/min | 47r/min | 47r/min | 47r/min | 47r/min |

| Rotor diameter (mm) | 300 | 350 | 450 | 550 | 650 | 850 |

| Production (t/h) | 0.5/0.8 | 0.8/1.2 | 2/3 | 3/4 | 4/5 | 7/8 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.