Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

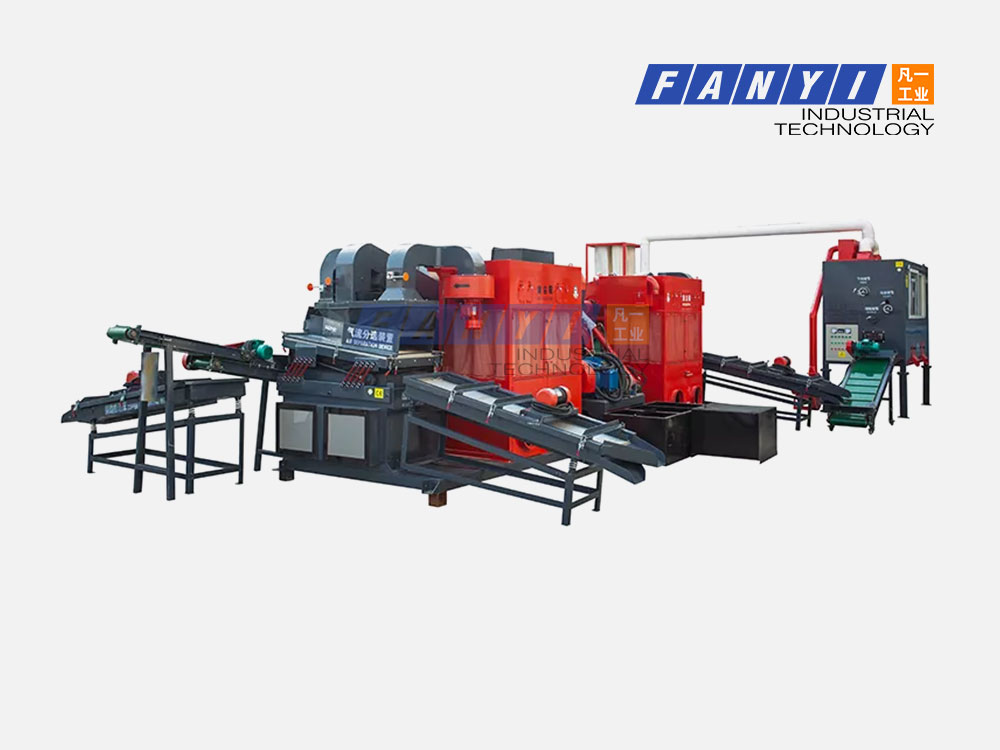

Cable Recycling Line is a production line specially designed for shredding waste cables. Through a series of processes such as shredding, granulating, separation and screening, it ensures the efficient separation of waste wires, produces high-quality copper rice and plastic particles, and maximizes the recycling of resources and reuse.

DESCRIPTION

Cable Recycling Line is also known as the “Copper Rice Machine” because the copper product it produces looks like rice grains. This production line has a simple structural design and is easy to maintain. The entire production line realizes intelligent control, high degree of automation, stable operation and excellent production efficiency. Its production capacity range is wide, ranging from 100kg/hour to 2000kg/hour, and the separation rate is as high as 99%.

1. PLC program control, uniform feeding and automatic alarm device, guarantee the maximum stability of the equipment running.

2. Compact structure, beautiful appearance, reasonable layout, safe and reliable.

3. The crusher, separator equipment and integrated equipment use platform type combination, which it’s convenient for move and transport, adding the flexibility of the whole line.

4. Crusher rotor adopts alternating shaft, making higher production efficiency, lower noise, and more stable operation.

5. The sorting efficiency of high-precision air flow separator is as high as 95%-99%.

6. Feedback system leads the semi-finished products to second grinder, improving the sorting efficiency.

7. Pulse dust catcher is effective in suppressing dust spillover, and the efficiency of dust removal is up to 99%.

8. Air filtration system can effectively avoid the dust produced by the second grinder.

9. Hydraulic system can open the second grinder body easily, and it’s easy for staff to do daily maintenance.

Belt Conveyor → Shaft Shredder → Magnetic Separator → Belt Conveyor → Feeder → Belt Conveyor → Crusher → Vibration Separation+Dust Removal → Static Separation / Fine Wires Vibrating Screen + Dust Removing Device

| Model | Input size (mm) |

Capacity (kg/h) |

Power (kW) |

Dimensions (mm) |

Weight (kg) |

| 400 | 0.5-20 | 300-400 | 15 | 1800*1300*1700 | 2850 |

| 600 | 0.5-20 | 500-600 | 37 | 2800*1800*2100 | 4200 |

| 800 | 0.5-20 | 700-800 | 45 | 2800*2000*2100 | 6500 |

| 1000 | 0.5-20 | 800-1000 | 55 | 2800*2500*2100 | 7800 |

Note: 1. All the equipment is suitable for wire dia within 80mm, and when the dia beyond 80mm, the peeling machine is needed.

2. Capacity May Vary with Different Materials and Feed Sizes.

3. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.