Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

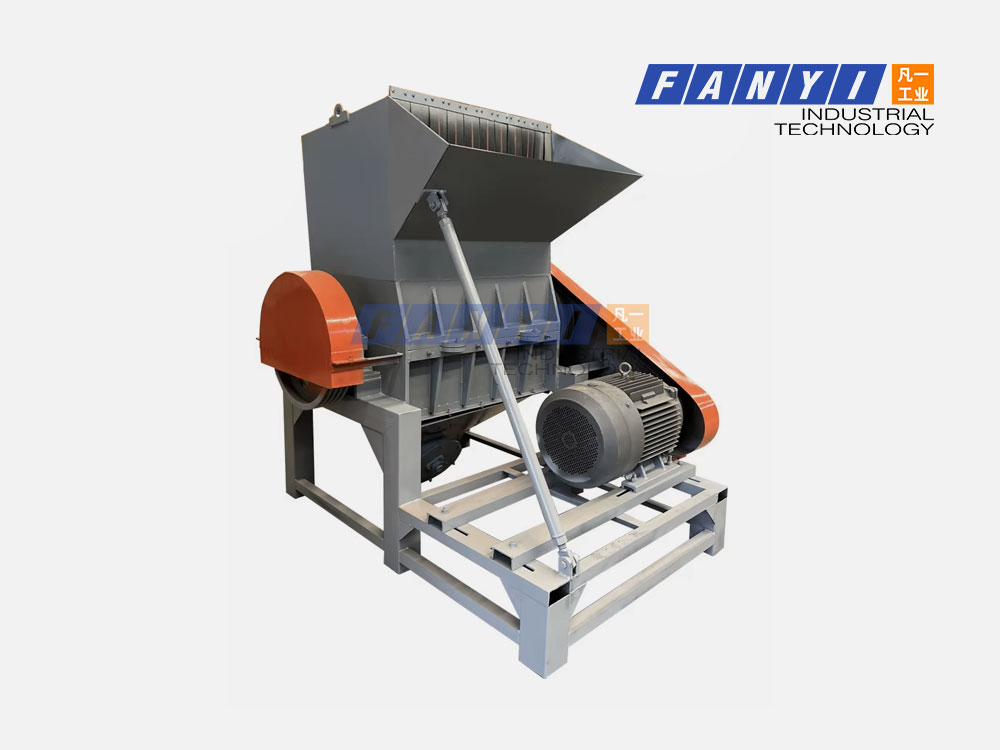

HDPE, PC, LDPE, PP, PET/PETE, PVC Plastic Recycling Machine Plastic crusher is used for crushing and recycling of various plastic, also known as plastic crusher. It has the characteristics of large crushing ability, high yield, and stable work performance. According to the production needs of different materials, it is equipped with a blade of different…

DESCRIPTION

Plastic crusher is used for crushing and recycling of various plastic, also known as plastic crusher. It has the characteristics of large crushing ability, high yield, and stable work performance. According to the production needs of different materials, it is equipped with a blade of different structures and a sieve with different pores. So as to achieve customer production needs.

It consists of a knife holder, a knife, a pulley, a brushing net, a feed bin, a base, and a discharge port. The belt wheel driven by the motor drives the knife holder to rotate at a high speed. The material is broken by the moving knife and the fixed knife, and then the screen is evenly sent out of the outlet.

HDPE, PC, LDPE, PP, PET/PETE, PVC Plastic Recycling Machine

| Model | Size(mm) length * width * height |

Power (kW) |

Output (kg/h) |

Weight (kg) |

Discharge size (mm) |

| 400 | 900x1100x1550 | 11 | 400-600 | 550 | 6-20 |

| 600 | 1200x1100x1750 | 15/18.5 | 600-1000 | 850 | |

| 800 | 1750x1550x2000 | 30/37 | 1000-2000 | 1400 | |

| 1000 | 1950x1900x2250 | 37/45 | 2000-3000 | 1800 | |

| 1200 | 2250x2000x2700 | 45/55 | 3000-4000 | 5500 |

Note: 1. Capacity May Vary with Different Materials and Feed Sizes.

2. The technical parameters above are not binding, we reserve the right to adjust according to the actual need.